Good quality Excavator Spare Parts Angular Contact Ball Bearings - Self-Aligning Ball Bearings – XINRI

Good quality Excavator Spare Parts Angular Contact Ball Bearings - Self-Aligning Ball Bearings – XINRI Detail:

Introduction

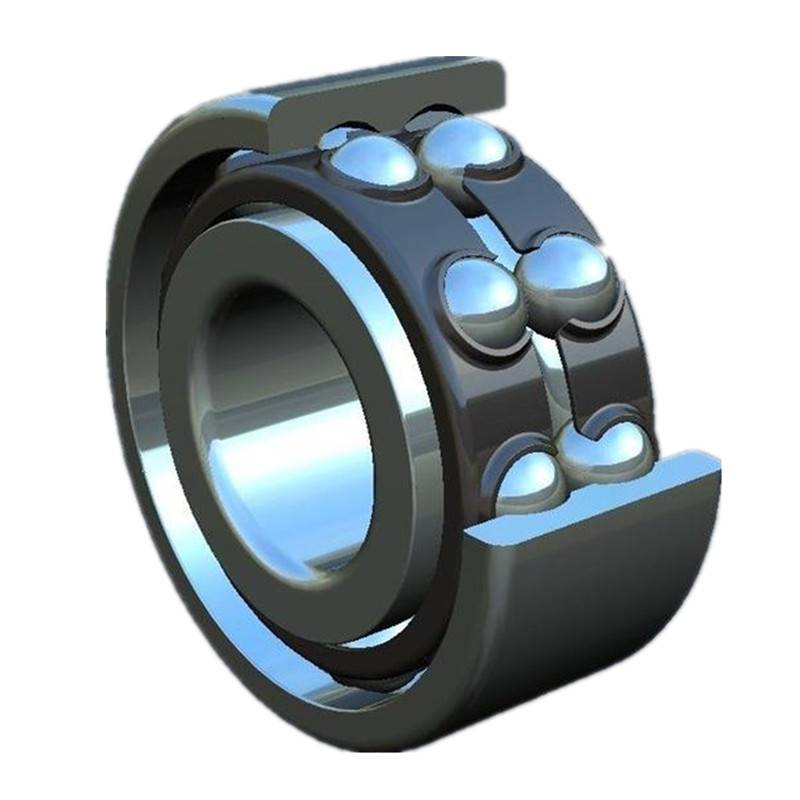

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. They are available open or sealed. The bearings are insensitive to angular misalignment of the shaft relative to the housing, which can be caused, for example, by shaft deflection.

Product Details

1.Self-aligning ball bearing has two kinds of structure: cylindrical hole and tapered hole, and the retainer is made of steel plate and synthetic resin. Its characteristic is that the outer ring raceway is spherical shape, with automatic centrality, can compensate the error caused by different concentricity and axial deflection, but the relative inclination of the inner and outer rings should not exceed 3 degrees.

2.It mainly bears radial load and can bear small axial load.The axial displacement of the shaft (housing) is limited within the clearance limit, with automatic centering performance, allowing the normal work under the condition of relatively small inclination of the inner and outer parts, suitable for parts where the coaxiality of the supporting seat hole cannot be strictly guaranteed.

Features and Benefits

● Accommodate static and dynamic misalignment

The bearings are self-aligning like spherical roller bearings or CARB bearings.

● Excellent high-speed performance

Self-aligning ball bearings generate less friction than any other type of rolling bearing, which enables them to run cooler even at high speeds.

● Minimum maintenance

Because of low heat generation, the bearing temperature is lower, leading to extended bearing life and maintenance intervals.

● Low friction

Very loose conformity between balls and outer ring keeps friction and frictional heat at low levels.

● Excellent light load performance

● Self-aligning ball bearings have low minimum load requirements.

Low noise

Self-aligning ball bearings can reduce noise and vibration levels, for example, in fans.

Application

Self-aligning ball bearing is suitable for heavy load and impact load, precision instruments, low noise motor, automobile, motorcycle, metallurgy, rolling mill, mining, petroleum, paper, cement, sugar and other industries and general machinery, etc.

Parameters

| SIZE | Principal dimensions | LOAD RATING | Speed ratings | ||||

| static | Reference speed | ||||||

| d[mm] | D[mm] | B[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| 1200 ETN9 | 10 | 30 | 9 | 5.53 | 1.18 | 56000 | 36000 |

| 2200 E-2RS1TN9 | 10 | 30 | 14 | 5.53 | 1.18 | 17000 | |

| 2200 ETN9 | 10 | 30 | 14 | 8.06 | 1.73 | 50000 | 34000 |

| 1201 ETN9 | 12 | 32 | 10 | 6.24 | 1.43 | 50000 | 32000 |

| 2201 E-2RS1TN9 | 12 | 32 | 14 | 6.24 | 1.43 | 16000 | |

| 2201 ETN9 | 12 | 32 | 14 | 8.52 | 1.9 | 45000 | 30000 |

| 1301 EM | 12 | 37 | 12 | 9.36 | 2.16 | 40000 | 28000 |

| 1301 ETN9 | 12 | 37 | 12 | 9.36 | 2.16 | 40000 | 28000 |

| 2301 | 12 | 37 | 17 | 11.7 | 2.7 | 38000 | 28000 |

| 1202 ETN9 | 15 | 35 | 11 | 7.41 | 1.76 | 45000 | 28000 |

| 2202 E-2RS1TN9 | 15 | 35 | 14 | 7.41 | 1.76 | 14000 | |

| 2202 ETN9 | 15 | 35 | 14 | 8.71 | 2.04 | 38000 | 26000 |

| 1302 ETN9 | 15 | 42 | 13 | 10.8 | 2.6 | 34000 | 24000 |

| 2302 E-2RS1TN9 | 15 | 42 | 17 | 10.8 | 2.6 | 12000 | |

| 2302 | 15 | 42 | 17 | 11.9 | 2.9 | 32000 | 24000 |

| 1203 ETN9 | 17 | 40 | 12 | 8.84 | 2.2 | 38000 | 24000 |

| 2203 E-2RS1TN9 | 17 | 40 | 16 | 8.84 | 2.2 | 12000 | |

| 2203 ETN9 | 17 | 40 | 16 | 10.6 | 2.55 | 34000 | 24000 |

| 1303 EM | 17 | 47 | 14 | 12.7 | 3.4 | 28000 | 20000 |

| 1303 ETN9 | 17 | 47 | 14 | 12.7 | 3.4 | 28000 | 20000 |

| 2303 E-2RS1TN9 | 17 | 47 | 19 | 12.7 | 3.4 | 11000 | |

| 2303 | 17 | 47 | 19 | 14.3 | 3.55 | 30000 | 22000 |

| 1204 EKTN9 | 20 | 47 | 14 | 12.7 | 3.4 | 32000 | 20000 |

| 1204 ETN9 | 20 | 47 | 14 | 12.7 | 3.4 | 32000 | 20000 |

| 2204 E-2RS1TN9 | 20 | 47 | 18 | 12.7 | 3.4 | 10000 | |

| 2204 ETN9 | 20 | 47 | 18 | 16.8 | 4.15 | 28000 | 20000 |

| 1304 ETN9 | 20 | 52 | 15 | 14.3 | 4 | 26000 | 18000 |

| 2304 E-2RS1TN9 | 20 | 52 | 21 | 14.3 | 4 | 9000 | |

| 2304 M | 20 | 52 | 21 | 18.2 | 4.75 | 26000 | 19000 |

| 2304 TN9 | 20 | 52 | 21 | 18.2 | 4.75 | 26000 | 19000 |

| 1205 EKTN9 | 25 | 52 | 15 | 14.3 | 4 | 28000 | 18000 |

| 1205 EM | 25 | 52 | 15 | 14.3 | 4 | 28000 | 18000 |

| 1205 ETN9 | 25 | 52 | 15 | 14.3 | 4 | 28000 | 18000 |

| 2205 E-2RS1KTN9 | 25 | 52 | 18 | 14.3 | 4 | 9000 | |

| 2205 E-2RS1TN9 | 25 | 52 | 18 | 14.3 | 4 | 9000 | |

| 2205 EKTN9 | 25 | 52 | 18 | 16.8 | 4.4 | 26000 | 18000 |

| 2205 ETN9 | 25 | 52 | 18 | 16.8 | 4.4 | 26000 | 18000 |

| 1305 EKTN9 | 25 | 62 | 17 | 19 | 5.4 | 22000 | 15000 |

| 1305 ETN9 | 25 | 62 | 17 | 19 | 5.4 | 22000 | 15000 |

| 2305 E-2RS1TN9 | 25 | 62 | 24 | 19 | 5.4 | 7500 | |

| 2305 M | 25 | 62 | 24 | 24.2 | 6.55 | 22000 | 16000 |

| 2305 ETN9 | 25 | 62 | 24 | 27 | 7.1 | 22000 | 16000 |

| 1206 EKTN9 | 30 | 62 | 16 | 15.6 | 4.65 | 24000 | 15000 |

| 1206 EM | 30 | 62 | 16 | 15.6 | 4.65 | 24000 | 15000 |

| 1206 ETN9 | 30 | 62 | 16 | 15.6 | 4.65 | 24000 | 15000 |

| 2206 E-2RS1KTN9 | 30 | 62 | 20 | 15.6 | 4.65 | 7500 | |

| 2206 E-2RS1TN9 | 30 | 62 | 20 | 15.6 | 4.65 | 7500 | |

| 2206 EKTN9 | 30 | 62 | 20 | 23.8 | 6.7 | 22000 | 15000 |

| 2206 ETN9 | 30 | 62 | 20 | 23.8 | 6.7 | 22000 | 15000 |

| 11206 TN9 | 30 | 62 | 48 | 15.6 | 4.65 | 6700 | |

| 1306 EKTN9 | 30 | 72 | 19 | 22.5 | 6.8 | 19000 | 13000 |

| 1306 ETN9 | 30 | 72 | 19 | 22.5 | 6.8 | 19000 | 13000 |

| 2306 E-2RS1KTN9 | 30 | 72 | 27 | 22.5 | 6.8 | 6700 | |

| 2306 E-2RS1TN9 | 30 | 72 | 27 | 22.5 | 6.8 | 6700 | |

| 2306 | 30 | 72 | 27 | 31.2 | 8.8 | 18000 | 13000 |

| 2306 K | 30 | 72 | 27 | 31.2 | 8.8 | 18000 | 13000 |

| 2306 M | 30 | 72 | 27 | 31.2 | 8.8 | 18000 | 13000 |

| 1207 EKTN9 | 35 | 72 | 17 | 19 | 6 | 20000 | 13000 |

| 1207 EM | 35 | 72 | 17 | 19 | 6 | 20000 | 13000 |

| 1207 ETN9 | 35 | 72 | 17 | 19 | 6 | 20000 | 13000 |

| 2207 E-2RS1KTN9 | 35 | 72 | 23 | 19 | 6 | 6300 | |

| 2207 E-2RS1TN9 | 35 | 72 | 23 | 19 | 6 | 6300 | |

| 2207 EKTN9 | 35 | 72 | 23 | 30.2 | 8.8 | 18000 | 12000 |

| 2207 ETN9 | 35 | 72 | 23 | 30.2 | 8.8 | 18000 | 12000 |

| 11207 TN9 | 35 | 72 | 52 | 19 | 6 | 5600 | |

| 1307 EKTN9 | 35 | 80 | 21 | 26.5 | 8.5 | 16000 | 11000 |

| 1307 ETN9 | 35 | 80 | 21 | 26.5 | 8.5 | 16000 | 11000 |

| 2307 E-2RS1KTN9 | 35 | 80 | 31 | 26.5 | 8.5 | 5600 | |

| 2307 E-2RS1TN9 | 35 | 80 | 31 | 26.5 | 8.5 | 5600 | |

| 2307 EKM | 35 | 80 | 31 | 39.7 | 11.2 | 16000 | 12000 |

| 2307 EKTN9 | 35 | 80 | 31 | 39.7 | 11.2 | 16000 | 12000 |

| 2307 EM | 35 | 80 | 31 | 39.7 | 11.2 | 16000 | 12000 |

| 2307 ETN9 | 35 | 80 | 31 | 39.7 | 11.2 | 16000 | 12000 |

| 1208 EKTN9 | 40 | 80 | 18 | 19.9 | 6.95 | 18000 | 11000 |

| 1208 ETN9 | 40 | 80 | 18 | 19.9 | 6.95 | 18000 | 11000 |

| 2208 E-2RS1KTN9 | 40 | 80 | 23 | 19.9 | 6.95 | 5600 | |

| 2208 E-2RS1TN9 | 40 | 80 | 23 | 19.9 | 6.95 | 5600 | |

| 2208 EKTN9 | 40 | 80 | 23 | 31.9 | 10 | 16000 | 11000 |

| 2208 ETN9 | 40 | 80 | 23 | 31.9 | 10 | 16000 | 11000 |

| 11208 TN9 | 40 | 80 | 56 | 19 | 6.55 | 5000 | |

| 1308 EKTN9 | 40 | 90 | 23 | 33.8 | 11.2 | 14000 | 9500 |

| 1308 EM | 40 | 90 | 23 | 33.8 | 11.2 | 14000 | 9500 |

| 1308 ETN9 | 40 | 90 | 23 | 33.8 | 11.2 | 14000 | 9500 |

| 2308 E-2RS1KTN9 | 40 | 90 | 33 | 33.8 | 11.2 | 5000 | |

| 2308 E-2RS1TN9 | 40 | 90 | 33 | 33.8 | 11.2 | 5000 | |

| 2308 EKTN9 | 40 | 90 | 33 | 54 | 16 | 14000 | 10000 |

| 2308 EM | 40 | 90 | 33 | 54 | 16 | 14000 | 10000 |

| 2308 ETN9 | 40 | 90 | 33 | 54 | 16 | 14000 | 10000 |

| 1209 EKTN9 | 45 | 85 | 19 | 22.9 | 7.8 | 17000 | 11000 |

| 1209 ETN9 | 45 | 85 | 19 | 22.9 | 7.8 | 17000 | 11000 |

| 2209 E-2RS1KTN9 | 45 | 85 | 23 | 22.9 | 7.8 | 5300 | |

| 2209 E-2RS1TN9 | 45 | 85 | 23 | 22.9 | 7.8 | 5300 | |

| 2209 EKTN9 | 45 | 85 | 23 | 32.5 | 10.6 | 15000 | 10000 |

| 2209 ETN9 | 45 | 85 | 23 | 32.5 | 10.6 | 15000 | 10000 |

| 11209 TN9 | 45 | 85 | 58 | 22.9 | 7.8 | 4500 | |

| 1309 EKTN9 | 45 | 100 | 25 | 39 | 13.4 | 12000 | 8500 |

| 1309 ETN9 | 45 | 100 | 25 | 39 | 13.4 | 12000 | 8500 |

| 2309 E-2RS1KTN9 | 45 | 100 | 36 | 39 | 13.4 | 4500 | |

| 2309 E-2RS1TN9 | 45 | 100 | 36 | 39 | 13.4 | 4500 | |

| 2309 EKTN9 | 45 | 100 | 36 | 63.7 | 19.3 | 13000 | 9000 |

| 2309 EM | 45 | 100 | 36 | 63.7 | 19.3 | 13000 | 9000 |

| 2309 ETN9 | 45 | 100 | 36 | 63.7 | 19.3 | 13000 | 9000 |

| 1210 EKTN9 | 50 | 90 | 20 | 26.5 | 9.15 | 16000 | 10000 |

| 1210 ETN9 | 50 | 90 | 20 | 26.5 | 9.15 | 16000 | 10000 |

| 2210 E-2RS1KTN9 | 50 | 90 | 23 | 22.9 | 8.15 | 4800 | |

| 2210 E-2RS1TN9 | 50 | 90 | 23 | 22.9 | 8.15 | 4800 | |

| 2210 EKTN9 | 50 | 90 | 23 | 33.8 | 11.2 | 14000 | 9500 |

| 2210 ETN9 | 50 | 90 | 23 | 33.8 | 11.2 | 14000 | 9500 |

| 11210 TN9 | 50 | 90 | 58 | 26.5 | 9.15 | 4300 | |

| 1310 EKTN9 | 50 | 110 | 27 | 43.6 | 14 | 12000 | 8000 |

| 1310 ETN9 | 50 | 110 | 27 | 43.6 | 14 | 12000 | 8000 |

| 2310 E-2RS1KTN9 | 50 | 110 | 40 | 43.6 | 14 | 4000 | |

| 2310 E-2RS1TN9 | 50 | 110 | 40 | 43.6 | 14 | 4000 | |

| 2310 M | 50 | 110 | 40 | 63.7 | 20 | 12000 | 8500 |

| 2310 | 50 | 110 | 40 | 63.7 | 20 | 14000 | 9500 |

| 2310 K | 50 | 110 | 40 | 63.7 | 20 | 14000 | 9500 |

| 1211 EKTN9 | 55 | 100 | 21 | 27.6 | 10.6 | 14000 | 9000 |

| 1211 ETN9 | 55 | 100 | 21 | 27.6 | 10.6 | 14000 | 9000 |

| 2211 E-2RS1KTN9 | 55 | 100 | 25 | 27.6 | 10.6 | 4300 | |

| 2211 E-2RS1TN9 | 55 | 100 | 25 | 27.6 | 10.6 | 4300 | |

| 2211 EKTN9 | 55 | 100 | 25 | 39 | 13.4 | 12000 | 8500 |

| 2211 ETN9 | 55 | 100 | 25 | 39 | 13.4 | 12000 | 8500 |

| 1311 EKTN9 | 55 | 120 | 29 | 50.7 | 18 | 11000 | 7500 |

| 1311 ETN9 | 55 | 120 | 29 | 50.7 | 18 | 11000 | 7500 |

| 2311 | 55 | 120 | 43 | 76.1 | 24 | 11000 | 7500 |

| 2311 K | 55 | 120 | 43 | 76.1 | 24 | 11000 | 7500 |

| 2311 KM | 55 | 120 | 43 | 76.1 | 24 | 11000 | 7500 |

| 2311 M | 55 | 120 | 43 | 76.1 | 24 | 11000 | 7500 |

| 1212 EKTN9 | 60 | 110 | 22 | 31.2 | 12.2 | 12000 | 8500 |

| 1212 ETN9 | 60 | 110 | 22 | 31.2 | 12.2 | 12000 | 8500 |

| 2212 E-2RS1TN9 | 60 | 110 | 28 | 31.2 | 12.2 | 3800 | |

| 2212 EKTN9 | 60 | 110 | 28 | 48.8 | 17 | 11000 | 8000 |

| 2212 ETN9 | 60 | 110 | 28 | 48.8 | 17 | 11000 | 8000 |

| 11212 TN9 | 60 | 110 | 62 | 31.2 | 12.2 | 3400 | |

| 1312 EKTN9 | 60 | 130 | 31 | 58.5 | 22 | 9000 | 6300 |

| 1312 ETN9 | 60 | 130 | 31 | 58.5 | 22 | 9000 | 6300 |

| 2312 | 60 | 130 | 46 | 87.1 | 28.5 | 9500 | 7000 |

| 2312 K | 60 | 130 | 46 | 87.1 | 28.5 | 9500 | 7000 |

| 2312 KM | 60 | 130 | 46 | 87.1 | 28.5 | 9500 | 7000 |

| 2312 M | 60 | 130 | 46 | 87.1 | 28.5 | 9500 | 7000 |

| 1213 EKTN9 | 65 | 120 | 23 | 35.1 | 14 | 11000 | 7000 |

| 1213 ETN9 | 65 | 120 | 23 | 35.1 | 14 | 11000 | 7000 |

| 2213 E-2RS1KTN9 | 65 | 120 | 31 | 35.1 | 14 | 3600 | |

| 2213 E-2RS1TN9 | 65 | 120 | 31 | 35.1 | 14 | 3600 | |

| 2213 EKTN9 | 65 | 120 | 31 | 57.2 | 20 | 10000 | 7000 |

| 2213 ETN9 | 65 | 120 | 31 | 57.2 | 20 | 10000 | 7000 |

| 1313 EKTN9 | 65 | 140 | 33 | 65 | 25.5 | 8500 | 6000 |

| 1313 ETN9 | 65 | 140 | 33 | 65 | 25.5 | 8500 | 6000 |

| 2313 | 65 | 140 | 48 | 95.6 | 32.5 | 9000 | 6300 |

| 2313 K | 65 | 140 | 48 | 95.6 | 32.5 | 9000 | 6300 |

| 2313 M | 65 | 140 | 48 | 95.6 | 32.5 | 9000 | 6300 |

| 1214 ETN9 | 70 | 125 | 24 | 35.8 | 14.6 | 11000 | 7000 |

| 2214 E-2RS1TN9 | 70 | 125 | 31 | 35.8 | 14.6 | 3400 | |

| 2214 | 70 | 125 | 31 | 44.2 | 17 | 10000 | 6700 |

| 1314 | 70 | 150 | 35 | 74.1 | 27.5 | 8500 | 6000 |

| 2314 | 70 | 150 | 51 | 111 | 37.5 | 8000 | 6000 |

| 2314 M | 70 | 150 | 51 | 111 | 37.5 | 8000 | 6000 |

| 1215 | 75 | 130 | 25 | 39 | 15.6 | 10000 | 6700 |

| 1215 K | 75 | 130 | 25 | 39 | 15.6 | 10000 | 6700 |

| 2215 EKTN9 | 75 | 130 | 31 | 58.5 | 22 | 9000 | 6300 |

| 2215 ETN9 | 75 | 130 | 31 | 58.5 | 22 | 9000 | 6300 |

| 1315 | 75 | 160 | 37 | 79.3 | 30 | 8000 | 5600 |

| 1315 K | 75 | 160 | 37 | 79.3 | 30 | 8000 | 5600 |

| 2315 | 75 | 160 | 55 | 124 | 43 | 7500 | 5600 |

| 2315 K | 75 | 160 | 55 | 124 | 43 | 7500 | 5600 |

| 2315 KM | 75 | 160 | 55 | 124 | 43 | 7500 | 5600 |

| 2315 M | 75 | 160 | 55 | 124 | 43 | 7500 | 5600 |

| 1216 | 80 | 140 | 26 | 39.7 | 17 | 9500 | 6000 |

| 1216 K | 80 | 140 | 26 | 39.7 | 17 | 9500 | 6000 |

| 2216 EKTN9 | 80 | 140 | 33 | 65 | 25.5 | 8500 | 6000 |

| 2216 ETN9 | 80 | 140 | 33 | 65 | 25.5 | 8500 | 6000 |

| 1316 | 80 | 170 | 39 | 88.4 | 33.5 | 7500 | 5300 |

| 1316 K | 80 | 170 | 39 | 88.4 | 33.5 | 7500 | 5300 |

| 2316 | 80 | 170 | 58 | 135 | 49 | 7000 | 5300 |

| 2316 K | 80 | 170 | 58 | 135 | 49 | 7000 | 5300 |

| 2316 KM | 80 | 170 | 58 | 135 | 49 | 7000 | 5300 |

| 2316 M | 80 | 170 | 58 | 135 | 49 | 7000 | 5300 |

| 1217 | 85 | 150 | 28 | 48.8 | 20.8 | 9000 | 5600 |

| 1217 K | 85 | 150 | 28 | 48.8 | 20.8 | 9000 | 5600 |

| 2217 | 85 | 150 | 36 | 58.5 | 23.6 | 8000 | 5600 |

| 2217 K | 85 | 150 | 36 | 58.5 | 23.6 | 8000 | 5600 |

| 1317 | 85 | 180 | 41 | 97.5 | 38 | 7000 | 4800 |

| 1317 K | 85 | 180 | 41 | 97.5 | 38 | 7000 | 4800 |

| 2317 KM | 85 | 180 | 60 | 140 | 51 | 6700 | 4800 |

| 2317 M | 85 | 180 | 60 | 140 | 51 | 6700 | 4800 |

| 1218 | 90 | 160 | 30 | 57.2 | 23.6 | 8500 | 5300 |

| 1218 K | 90 | 160 | 30 | 57.2 | 23.6 | 8500 | 5300 |

| 2218 | 90 | 160 | 40 | 70.2 | 28.5 | 7500 | 5300 |

| 2218 K | 90 | 160 | 40 | 70.2 | 28.5 | 7500 | 5300 |

| 2218 KM | 90 | 160 | 40 | 70.2 | 28.5 | 7500 | 5300 |

| 1318 | 90 | 190 | 43 | 117 | 44 | 6700 | 4500 |

| 1318 K | 90 | 190 | 43 | 117 | 44 | 6700 | 4500 |

| 2318 KM | 90 | 190 | 64 | 151 | 57 | 6300 | 4500 |

| 2318 M | 90 | 190 | 64 | 151 | 57 | 6300 | 4500 |

| 1219 | 95 | 170 | 32 | 63.7 | 27 | 8000 | 5000 |

| 1219 K | 95 | 170 | 32 | 63.7 | 27 | 8000 | 5000 |

| 2219 KM | 95 | 170 | 43 | 83.2 | 34.5 | 7000 | 5000 |

| 2219 M | 95 | 170 | 43 | 83.2 | 34.5 | 7000 | 5000 |

| 1319 | 95 | 200 | 45 | 133 | 51 | 6300 | 4300 |

| 1319 K | 95 | 200 | 45 | 133 | 51 | 6300 | 4300 |

| 2319 M | 95 | 200 | 67 | 165 | 64 | 6000 | 4500 |

| 1220 | 100 | 180 | 34 | 68.9 | 30 | 7500 | 4800 |

| 1220 K | 100 | 180 | 34 | 68.9 | 30 | 7500 | 4800 |

| 2220 | 100 | 180 | 46 | 97.5 | 40.5 | 6700 | 4800 |

| 2220 K | 100 | 180 | 46 | 97.5 | 40.5 | 6700 | 4800 |

| 2220 KM | 100 | 180 | 46 | 97.5 | 40.5 | 6700 | 4800 |

| 2220 M | 100 | 180 | 46 | 97.5 | 40.5 | 6700 | 4800 |

| 1320 | 100 | 215 | 47 | 143 | 57 | 6000 | 4000 |

| 1320 K | 100 | 215 | 47 | 143 | 57 | 6000 | 4000 |

| 1320 KM | 100 | 215 | 47 | 143 | 57 | 6000 | 4000 |

| 2320 M | 100 | 215 | 73 | 190 | 80 | 5600 | 4000 |

| 1222 | 110 | 200 | 38 | 88.4 | 39 | 6700 | 4300 |

| 1222 K | 110 | 200 | 38 | 88.4 | 39 | 6700 | 4300 |

| 2222 | 110 | 200 | 53 | 124 | 52 | 6000 | 4300 |

| 2222 K | 110 | 200 | 53 | 124 | 52 | 6000 | 4300 |

| 2222 KM | 110 | 200 | 53 | 124 | 52 | 6000 | 4300 |

| 2222 M | 110 | 200 | 53 | 124 | 52 | 6000 | 4300 |

| 1322 KM | 110 | 240 | 50 | 163 | 72 | 5300 | 3600 |

| 1322 M | 110 | 240 | 50 | 163 | 72 | 5300 | 3600 |

| 1224 KM | 120 | 215 | 42 | 119 | 53 | 6300 | 4000 |

| 1224 M | 120 | 215 | 42 | 119 | 53 | 6300 | 4000 |

| 1226 KM | 130 | 230 | 46 | 127 | 58.5 | 5600 | 3600 |

| 1226 M | 130 | 230 | 46 | 127 | 58.5 | 5600 | 3600 |

| 13030 | 150 | 225 | 56 | 57.2 | 23.6 | 5600 | 3400 |

| 13940 | 200 | 280 | 60 | 60.5 | 29 | 4300 | 2600 |

| 13944 | 220 | 300 | 60 | 60.5 | 30.5 | 3800 | 2400 |

| 13948 | 240 | 320 | 60 | 60.5 | 32 | 3800 | 2200 |

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for Good quality Excavator Spare Parts Angular Contact Ball Bearings - Self-Aligning Ball Bearings – XINRI , The product will supply to all over the world, such as: Ghana, UK, Buenos Aires, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.