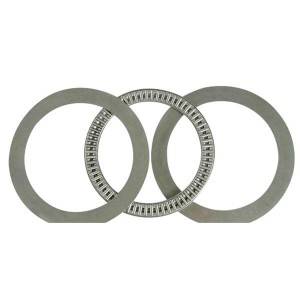

Needle Roller Thrust Bearings

Introduction

Needle roller thrust bearings are fitted with a form-stable cage to reliably retain and guide a large number of needle rollers. Needle roller thrust bearings provide a high degree of stiffness within a minimum axial space. In applications where the faces of adjacent machine components can serve as raceways, needle roller thrust bearings take up no more space than a conventional thrust washer.

Needle thrust roller bearings may be complete bearing assemblies with thrust washers and roller cage assemblies, or needle roller and cage assemblies. The rolling needle is hardened and finely ground for optimal load distribution. When these requirements are not met, the use of thrust washers is strongly recommended.

Features and Benefits

● Accommodate heavy axial loads and peak loads

The very small diameter deviation of the rollers within one assembly enables these bearings to accommodate heavy axial loads and peak loads.

● Extended bearing service life

To prevent stress peaks, the roller ends are relieved slightly to modify the line contact between the raceway and rollers.

Structural and Features

Needle thrust roller bearings may be complete bearing assemblies with thrust washers and roller cage assemblies, or needle roller and cage assemblies. The rolling needle is hardened and finely ground for optimal load distribution. When these requirements are not met, the use of thrust washers is strongly recommended.

Parameters

| SIZE | DIMENSION | Basic lo ad ratings |

Fatigue load limit | Speed ratings | ||||

| dynamic | static | Reference speed | Limiting speed | |||||

| d[mm] | D[mm] | Dw[mm] | C[kN] | C0[kN] | Pu[kN] | [r/min] | [r/min] | |

| AXK 0414 TN | 4 | 14 | 2 | 4.15 | 8.3 | 0.95 | 7500 | 15000 |

| AXK 0515 TN | 5 | 15 | 2 | 4.5 | 9.5 | 1.08 | 6700 | 14000 |

| AXK 0619 TN | 6 | 19 | 2 | 6.3 | 16 | 1.86 | 6000 | 12000 |

| AXK 0821 TN | 8 | 21 | 2 | 7.2 | 20 | 2.32 | 5600 | 11000 |

| AXK 1024 | 10 | 24 | 2 | 8.5 | 26 | 3 | 5300 | 10000 |

| AXK 1024 | 10 | 24 | 2 | 8.5 | 26 | 3 | 5300 | 10000 |

| AXK 1226 | 12 | 26 | 2 | 9.15 | 30 | 3.45 | 5000 | 10000 |

| AXK 1226 | 12 | 26 | 2 | 9.15 | 30 | 3.45 | 5000 | 10000 |

| AXK 1528 | 15 | 28 | 2 | 10.4 | 37.5 | 4.3 | 4800 | 9500 |

| AXK 1528 | 15 | 28 | 2 | 10.4 | 37.5 | 4.3 | 4800 | 9500 |

| AXK 1730 | 17 | 30 | 2 | 11 | 40.5 | 4.75 | 4500 | 9500 |

| AXK 2035 | 20 | 35 | 2 | 12 | 47.5 | 5.6 | 4300 | 8500 |

| AXK 2035 | 20 | 35 | 2 | 12 | 47.5 | 5.6 | 4300 | 8500 |

| AXK 2542 | 25 | 42 | 2 | 13.4 | 60 | 6.95 | 3800 | 7500 |

| AXK 2542 | 25 | 42 | 2 | 13.4 | 60 | 6.95 | 3800 | 7500 |

| AXK 3047 | 30 | 47 | 2 | 15 | 72 | 8.3 | 3600 | 7000 |

| AXK 3047 | 30 | 47 | 2 | 15 | 72 | 8.3 | 3600 | 7000 |

| AXK 3552 | 35 | 52 | 2 | 16.6 | 83 | 9.8 | 3200 | 6300 |

| AXK 3552 | 35 | 52 | 2 | 16.6 | 83 | 9.8 | 3200 | 6300 |

| AXK 4060 | 40 | 60 | 3 | 25 | 114 | 13.7 | 2800 | 5600 |

| AXK 4060 | 40 | 60 | 3 | 25 | 114 | 13.7 | 2800 | 5600 |

| AXK 4565 | 45 | 65 | 3 | 27 | 127 | 15.3 | 2600 | 5300 |

| AXK 4565 | 45 | 65 | 3 | 27 | 127 | 15.3 | 2600 | 5300 |

| AXK 5070 | 50 | 70 | 3 | 28.5 | 143 | 17 | 2400 | 5000 |

| AXK 5070 | 50 | 70 | 3 | 28.5 | 143 | 17 | 2400 | 5000 |

| AXK 5578 | 55 | 78 | 3 | 34.5 | 186 | 22.4 | 2200 | 4300 |

| AXK 6085 | 60 | 85 | 3 | 37.5 | 232 | 28.5 | 2200 | 4300 |

| AXK 6590 | 65 | 90 | 3 | 39 | 255 | 31 | 2000 | 4000 |

| AXK 7095 | 70 | 95 | 4 | 49 | 255 | 31 | 1800 | 3600 |

| AXK 75100 | 75 | 100 | 4 | 50 | 265 | 32.5 | 1700 | 3400 |

| AXK 80105 | 80 | 105 | 4 | 51 | 280 | 34 | 1700 | 3400 |

| AXK 85110 | 85 | 110 | 4 | 52 | 290 | 35.5 | 1700 | 3400 |

| AXK 90120 | 90 | 120 | 4 | 65.5 | 405 | 49 | 1500 | 3000 |

| AXK 100135 | 100 | 135 | 4 | 76.5 | 560 | 65.5 | 1400 | 2800 |

| AXK 110145 | 110 | 145 | 4 | 81.5 | 620 | 72 | 1300 | 2600 |

| AXK 120155 | 120 | 155 | 4 | 86.5 | 680 | 76.5 | 1300 | 2600 |

| AXK 130170 | 130 | 170 | 5 | 112 | 830 | 93 | 1100 | 2200 |

| AXK 140180 | 140 | 180 | 5 | 116 | 900 | 96.5 | 1000 | 2000 |

| AXK 150190 | 150 | 190 | 5 | 120 | 950 | 102 | 1000 | 2000 |

| AXK 160200 | 160 | 200 | 5 | 125 | 1000 | 106 | 950 | 1900 |