In the automotive industry, precision is key. Every component must work in harmony to ensure that vehicles perform efficiently, safely, and reliably. Among the most critical of these components are auto bearings. These precision-engineered parts play a vital role in the smooth operation of vehicles, affecting everything from fuel efficiency to safety and longevity. As a leading provider of high-quality bearings, “Xinri Bearing” is dedicated to supplying the automotive industry with the precision parts needed to keep vehicles running at their best. In this article, we will explore the importance of auto bearings, their various types, and the precision engineering that goes into creating these essential automotive parts.

The Role of Auto Bearings in Vehicles

Auto bearings are integral components in virtually every part of a vehicle that involves rotation. They support the vehicle’s weight, minimize friction, and ensure the smooth rotation of wheels, engines, and other moving parts. The precision of these bearings directly impacts the performance and safety of the vehicle.

- Wheel Bearings

- Function: Wheel bearings are located in the hub assembly, where they allow the wheels to rotate freely while supporting the vehicle’s weight. These bearings are crucial for maintaining the vehicle’s stability and handling.

- Precision Parameters: The inner and outer rings of wheel bearings must be machined to tolerances within micrometers (typically ±2 micrometers) to ensure a perfect fit and smooth operation. Xinri Bearing’s wheel bearings are engineered with precision to maintain these tight tolerances, contributing to enhanced vehicle performance and safety.

- Engine Bearings

- Function: Engine bearings are used in the crankshaft and connecting rods, where they reduce friction between the moving parts of the engine. This ensures smooth engine operation and longevity.

- Precision Parameters: The precision of engine bearings is critical, with tolerances as tight as ±1 micrometer. This precision ensures that the bearings can withstand high temperatures and pressures while maintaining smooth engine performance. Xinri Bearing’s engine bearings are designed to meet these exacting standards, offering durability and reliability in even the most demanding engine environments.

- Transmission Bearings

- Function: Transmission bearings support the gears and shafts within the transmission, reducing friction and wear as the vehicle shifts gears. They are essential for smooth gear changes and overall transmission efficiency.

- Precision Parameters: Transmission bearings must be precision-engineered to handle the high speeds and loads associated with gear shifts. Tolerances for these bearings are typically within ±3 micrometers. Xinri Bearing’s transmission bearings are crafted with the utmost precision, ensuring smooth and efficient gear shifts for enhanced driving comfort.

Precision Engineering in Auto Bearings

The precision required in automotive bearings cannot be overstated. These components are subject to high loads, extreme temperatures, and constant stress, making precision engineering crucial for their performance and durability.

- Material Selection

- The choice of materials for auto bearings is fundamental to their performance. High-quality steel, such as SAE 52100 chrome steel, is commonly used for its hardness and resistance to wear and fatigue. Xinri Bearing uses only premium-grade materials in its bearings, ensuring they can withstand the rigors of automotive applications.

- Advanced Manufacturing Techniques

- The manufacturing of auto bearings involves several advanced techniques, including precision grinding, heat treatment, and surface finishing. Precision grinding is used to achieve the tight tolerances required, while heat treatment processes like quenching and tempering are applied to enhance the hardness and strength of the bearings.

- Surface Finish: The surface finish of bearing components is also critical, as even minor imperfections can lead to increased friction and premature wear. Xinri Bearing utilizes advanced surface finishing techniques to achieve surface roughness values as low as Ra 0.1 micrometers, resulting in smoother operation and longer bearing life.

- Quality Control

- Rigorous quality control measures are essential in the production of auto bearings. At Xinri Bearing, every bearing undergoes thorough inspection using precision measurement tools like coordinate measuring machines (CMMs) and roundness testers. These tools ensure that each bearing meets the exacting specifications required for automotive applications.

- Testing: Bearings are also subjected to performance testing, including load testing, noise testing, and durability testing, to verify their reliability in real-world conditions. Xinri Bearing’s commitment to quality ensures that every bearing delivers consistent performance and meets the highest standards of safety and reliability.

The Impact of Precision Bearings on Vehicle Performance

Precision bearings have a direct impact on several key aspects of vehicle performance:

- Fuel Efficiency

- By reducing friction in the drivetrain and other rotating components, precision bearings help improve fuel efficiency. This is particularly important in modern vehicles, where every component is optimized for energy savings. Xinri Bearing’s low-friction bearings are designed to minimize energy losses, contributing to better fuel economy.

- Safety

- Bearings play a crucial role in the safety of a vehicle. For example, wheel bearings that fail can lead to loss of control, while engine bearing failure can cause catastrophic engine damage. Precision-engineered bearings from Xinri Bearing are built to withstand extreme conditions, ensuring the safety and reliability of the vehicle.

- Longevity

- High-quality bearings extend the life of the vehicle by reducing wear and tear on critical components. This not only enhances the durability of the vehicle but also reduces maintenance costs over time. Xinri Bearing’s products are designed for long service life, offering superior performance throughout their lifespan.

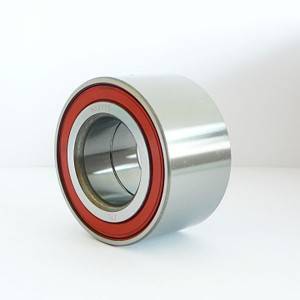

WHEEL HUB BEARING

Market Trends and Trade Data

The global market for automotive bearings is expanding, driven by the increasing demand for vehicles and the push for higher efficiency and performance. According to recent trade data, the global automotive bearing market was valued at approximately USD 40 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth is fueled by advancements in electric vehicles (EVs), where precision bearings play a critical role in reducing friction and improving efficiency.

Xinri Bearing is at the forefront of this market, supplying precision-engineered bearings to automotive manufacturers worldwide. Our commitment to quality, innovation, and customer satisfaction has made us a trusted partner in the automotive industry.

Conclusion

Auto bearings are among the most critical precision parts in a vehicle, affecting everything from fuel efficiency and safety to overall vehicle performance and longevity. The precision engineering that goes into these components is what sets high-quality bearings apart from the rest. At Xinri Bearing, we are dedicated to providing the automotive industry with the highest quality bearings, designed to meet the exacting standards of modern vehicles. Whether for wheels, engines, or transmissions, Xinri Bearing’s precision-engineered products ensure that vehicles operate smoothly, efficiently, and safely, mile after mile.

Product: Wheel Hub Bearing

Post time: Aug-13-2024