The removal of the bearing should be carried out with the same care as the installation. Be careful not to damage the bearing and various parts, especially the disassembly of the interference fit bearing, which is difficult to operate. Therefore, in the design stage, it is necessary to consider the ease of disassembly in advance, and it is also very important to design and manufacture disassembly tools as needed. When disassembling, study the disassembly method and sequence according to the drawings, and investigate the matching conditions of the bearing to obtain a foolproof disassembly operation.

1. Disassembly of the outer ring

Disassemble the outer ring of the interference fit, set several screws for the outer ring to squeeze the screw on the circumference of the casing in advance, and tighten the screw evenly while disassembling. These screw holes are usually covered with blind plugs, separable bearings such as tapered roller bearings, and several incisions are set on the shoulder of the housing. Use spacers to remove them with a press, or tap them lightly to remove them.

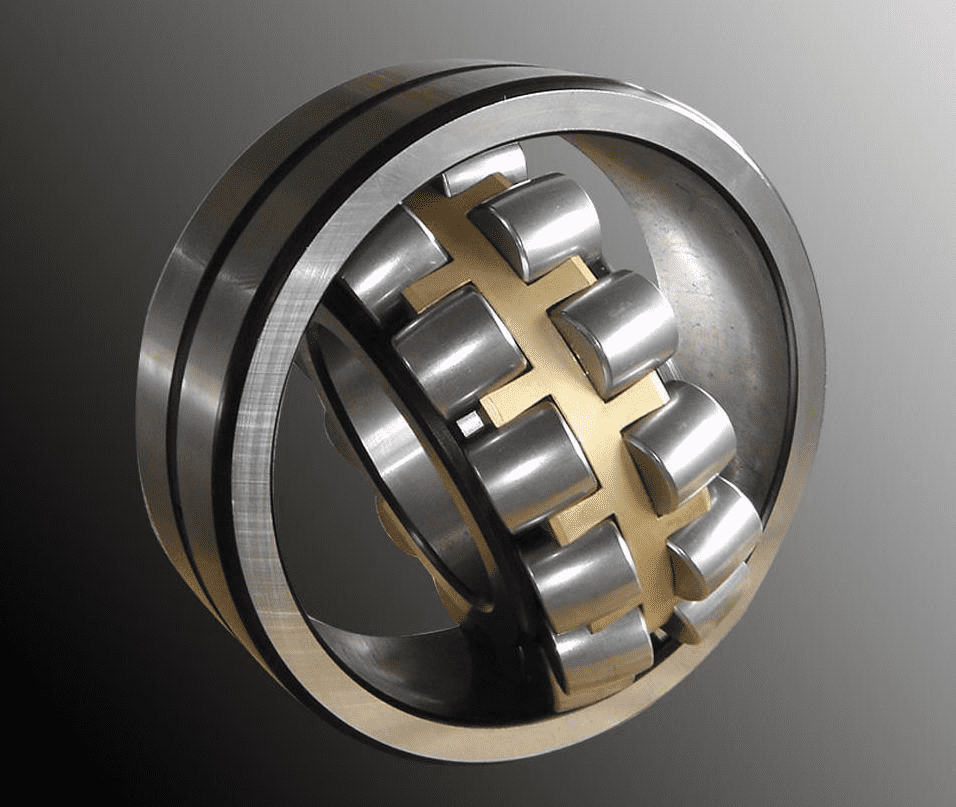

2. Disassembly of cylindrical bore bearing

The disassembly of the inner ring can be easily pulled out by a pressure machine. At this time, pay attention to let the inner ring bear its pulling force.

The disassembly of the inner ring of the large bearing adopts the hydraulic method. Oil pressure is applied through the oil hole provided on the shaft to make it easy to pull out. For bearings with large widths, the hydraulic method is used in combination with the pulling jig for disassembly.

The inner ring disassembly of NU and NJ cylindrical roller bearings can use the induction heating method. A method of drawing by heating the part in a short time to expand the inner ring.

3. Disassembly of tapered bore bearing

Disassemble the relatively small bearing with an adapter sleeve, use the stopper fastened on the shaft to support the inner ring, turn the nut back several times, and use the spacer to knock it out with a hammer.

For large bearings, it is easier to disassemble using oil pressure. Oil is pressurized in the oil hole on the tapered hole shaft to expand the inner ring and disassemble the bearing. During operation, the bearing may come out suddenly, so it is better to use the nut as a stopper.

Post time: Sep-19-2022