Tandem thrust cylindrical roller bearings are a kind of bearings, which are widely used in the rubber industry and mechanical equipment. Today, the editor will introduce to you the knowledge of the structure and model of tandem thrust cylindrical roller bearings, hoping to help everyone in the understanding of tandem thrust cylindrical roller bearings.

●Structure type

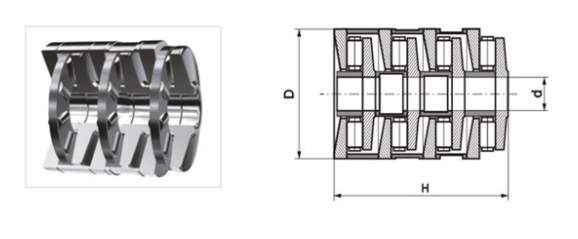

1.Basic Tandem Thrust Cylindrical Roller Bearing The basic tandem thrust cylindrical roller bearing connects the shaft washer, seat ring and roller with the cage assembly through an elastic spacer. This type of bearing has a separable structure with detachable parts. It is recommended to carefully install and disassemble in accordance with the numbering sequence provided in the following table when using it.

2.Sleeve-type tandem cylindrical roller bearings. Sleeve-type tandem cylindrical roller bearings are bearings with sleeves on the outside of the basic tandem cylindrical roller bearings. They can be assembled and disassembled as a whole.

3.Shaft type tandem cylindrical roller bearing with shaft type tandem thrust cylindrical roller bearing is a kind of modified structure bearing. A shaft is penetrated in the inner hole of the basic type tandem cylindrical roller bearing, and elasticity is used. The lock ring secures the bearing to the shaft.

This type of bearing parts are inseparable, and the overall assembly and disassembly are very convenient.

●Structural features

Tandem thrust cylindrical roller bearings have limited radial cross-section, relatively large axial load capacity, long working life and minimal friction loss.

●Model

Ordinary tandem thrust cylindrical roller bearings (d=4~420), shaft type tandem cylindrical roller bearings (d=4~34), sleeve type tandem thrust cylindrical roller bearings.

●The use requirements of the use of tandem bearings, should comply with the following requirements:

1.Preload: add 1% of the basic rated dynamic load of the bearing. For the basic rated dynamic load of each tandem bearing, see the following table.

2.Radial guide: Full complement cylindrical roller bearings or needle roller bearings can be used.

3.Elimination of tilt: In the machining of the supporting parts, any tilt must be eliminated, that is, the tilt of the supporting surface.

4.Tolerance of fit: To ensure correct operation, recommended tolerance of fit: shaft f6, seat hole F7.

5.Bearing lubrication: Tandem bearings must always be lubricated with dilute lubricating oil.

6. Bearing installation: Do not hit the bearing parts with hammers or other heavy objects during bearing installation and disassembly.

●Application

Application example of tandem bearings: Because tandem thrust cylindrical roller bearings have limited radial cross-section, relatively large axial load capacity, long-term working life and relatively small friction loss: so the parallel twin screw in the rubber and plastic industry The extruder gear transmission box has been extremely successfully applied, and it will also be popularized and applied in other mechanical equipment.

Post time: May-19-2021