In the world of industrial machinery and heavy-duty applications, the choice of components can significantly impact the performance, efficiency, and longevity of equipment. One of the most critical components in these systems is the ball bearing. When it comes to selecting durable ball bearings for heavy-duty applications, Xinri, a renowned bearings manufacturer, stands out as a leader in the industry. This article delves into the intricacies of choosing the right ball bearings and highlights Xinri’s contributions to the field.

Understanding the Importance of Ball Bearings

Ball bearings are a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The primary purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. In heavy-duty applications, where machinery is subject to extreme conditions and loads, the durability and reliability of ball bearings are paramount.

The choice of ball bearings can affect the operation of machinery in several ways. Poorly chosen bearings can lead to increased friction, wear, and tear, resulting in frequent maintenance, unexpected downtime, and increased operational costs. Therefore, selecting the right ball bearings is crucial for the smooth and efficient functioning of heavy-duty equipment.

The Role of Xinri in the Bearings Industry

Xinri has been a pioneering force in the bearings industry, renowned for its commitment to quality, innovation, and customer satisfaction. With decades of experience, Xinri has developed a comprehensive range of ball bearings designed to meet the demanding requirements of heavy-duty applications.

Xinri’s ball bearings are engineered to withstand high loads, extreme temperatures, and harsh environmental conditions. The company employs cutting-edge technology and high-quality materials to ensure that their bearings offer superior performance and longevity.

Key Features of Xinri Ball Bearings

When selecting ball bearings for heavy-duty applications, several key features must be considered. Xinri’s ball bearings are designed with these features in mind, ensuring that they meet the rigorous demands of industrial applications:

- Material Quality: Xinri uses high-grade steel and advanced alloys to manufacture their ball bearings, ensuring maximum strength and durability.

- Precision Engineering: The bearings are engineered with precision to provide smooth operation, reduce friction, and minimize wear.

- Load Capacity: Xinri ball bearings are designed to handle high radial and axial loads, making them suitable for heavy-duty applications.

- Temperature Resistance: The bearings are capable of operating in extreme temperatures, ensuring reliability in harsh environments.

- Corrosion Resistance: Special coatings and materials are used to protect the bearings from corrosion, extending their lifespan.

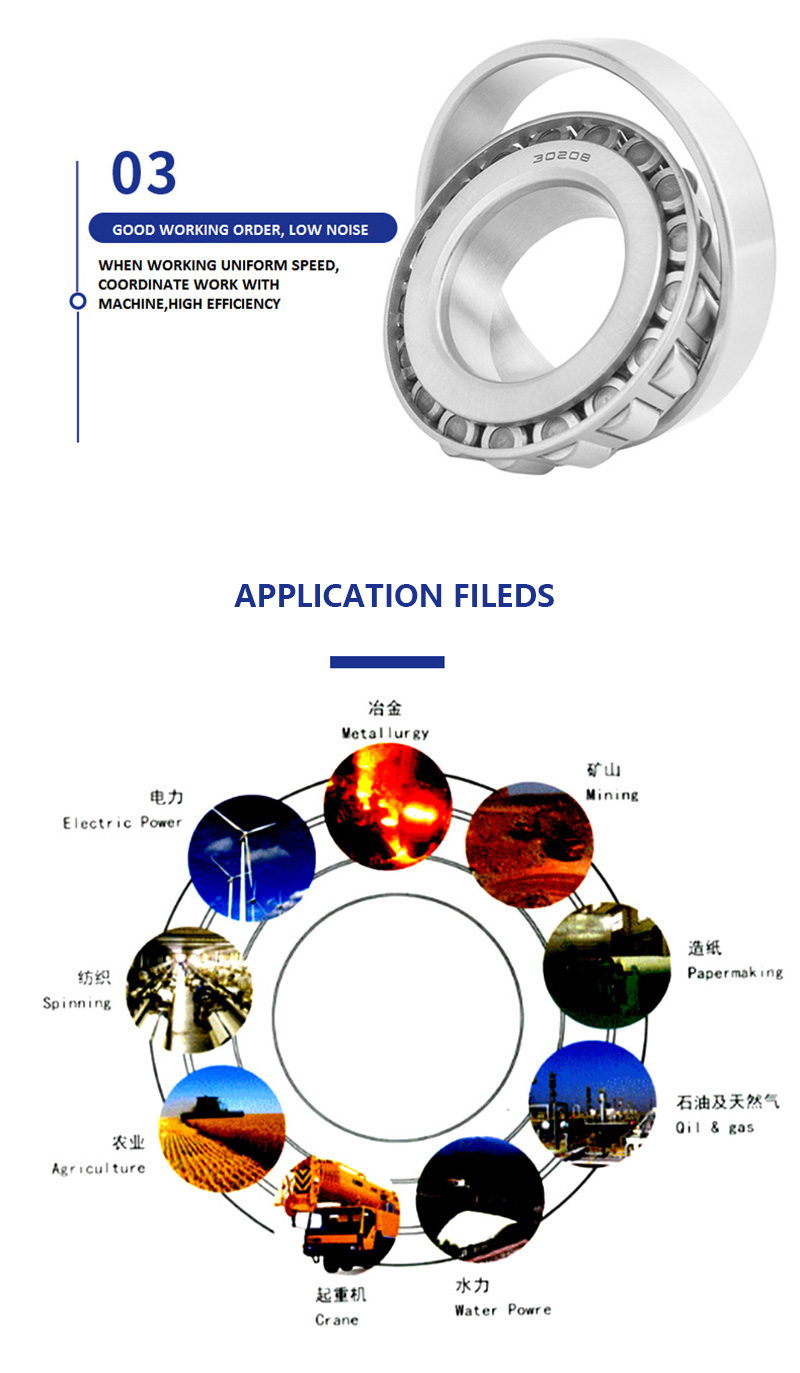

Applications of Xinri Ball Bearings

Xinri’s ball bearings find applications across a wide range of industries, each with its own set of challenges and requirements. Some of the key sectors where Xinri ball bearings are extensively used include:

- Automotive Industry: In the automotive sector, ball bearings are essential for the smooth operation of engines, transmissions, and wheel hubs. Xinri’s bearings ensure reliability and performance in vehicles under various conditions.

- Aerospace Industry: The aerospace industry demands high-performance bearings that can withstand extreme temperatures and pressures. Xinri’s precision-engineered bearings are crucial for aircraft engines and other critical components.

- Manufacturing Industry: In manufacturing, machinery and equipment rely on durable ball bearings to maintain efficiency and productivity. Xinri provides solutions that reduce downtime and enhance operational efficiency.

- Construction Industry: Heavy machinery used in construction requires robust bearings to handle heavy loads and challenging environments. Xinri’s ball bearings are designed to meet these demands.

- Energy Sector: In the energy sector, particularly in wind turbines and hydroelectric plants, ball bearings play a vital role in ensuring continuous operation. Xinri’s bearings offer reliability and longevity in these applications.

Factors to Consider When Choosing Ball Bearings

Choosing the right ball bearings for heavy-duty applications involves considering several critical factors. Xinri’s expertise in the field provides valuable insights into these considerations:

Load Requirements

The first step in selecting ball bearings is understanding the load requirements of the application. This includes both radial and axial loads that the bearings will need to support. Xinri offers a range of bearings with varying load capacities to suit different applications.

Operating Environment

The environment in which the bearings will operate is another crucial factor. Factors such as temperature, humidity, and exposure to corrosive substances can affect bearing performance. Xinri’s bearings are designed to withstand harsh conditions, making them ideal for challenging environments.

Speed and Precision

The speed at which the machinery operates and the level of precision required are also important considerations. Xinri’s precision-engineered bearings ensure smooth operation at high speeds, reducing friction and wear.

Maintenance and Longevity

Maintenance requirements and the expected lifespan of the bearings are essential factors to consider. Xinri’s ball bearings are designed for durability and low maintenance, reducing the need for frequent replacements and minimizing downtime.

Conclusion

In conclusion, selecting the right ball bearings for heavy-duty applications is a critical decision that can significantly impact the performance and longevity of machinery. Xinri, as a leading bearings manufacturer, offers a comprehensive range of high-quality ball bearings designed to meet the demanding requirements of various industries.

By considering factors such as load requirements, operating environment, speed, precision, and maintenance needs, Xinri ensures that their ball bearings provide optimal performance and reliability. With a commitment to quality and innovation, Xinri continues to be a trusted partner for industries seeking durable and efficient ball bearing solutions.

Whether in the automotive, aerospace, manufacturing, construction, or energy sector, Xinri’s ball bearings are engineered to deliver exceptional performance, making them the ideal choice for heavy-duty applications.

For more information on Xinri’s range of ball bearings and to explore how they can meet your specific application needs, visit their website or contact their expert team today. Xinri is dedicated to providing tailored solutions that enhance the efficiency and reliability of your machinery, ensuring your operations run smoothly and effectively.

Tags:ball bearing,cluth bearing,bearing manufacturer

Post time: Dec-31-2024