The actual clearance of the motor bearing at work is related to the bearing load, speed, lubrication, temperature rise, vibration, design structure and surface roughness of the matching table. When choosing, it should be selected according to the specific situation. The clearance after subtracting the expansion or contraction of the ring due to interference fit when the bearing is installed on the shaft or in the housing is called “installation clearance” from the theoretical clearance. The clearance obtained by adding and subtracting the dimensional variation due to the temperature difference inside the bearing from the mounting clearance is called “effective clearance”. The clearance when the bearing is installed on the machine under a certain load and rotates, that is, the clearance after the effective clearance plus the elastic deformation caused by the bearing load is called “working clearance”.

As shown in the figure, when the working clearance is slightly negative, the fatigue life of the bearing is the longest, but the fatigue life decreases significantly with the increase of the negative clearance. Therefore, when selecting the bearing clearance, it is generally advisable to make the working clearance zero or slightly positive. When selecting bearing clearance, the following aspects should be considered: 1. The working conditions of the bearing, such as load, temperature, speed, vibration, etc.; 2. The requirements for the performance of the bearing (rotational accuracy, friction torque, vibration, noise); 3. When the bearing, the shaft and the housing hole are in an interference fit, the bearing clearance is reduced; 4. When the bearing is working, the temperature difference between the inner and outer rings causes the bearing clearance to decrease; 5. Due to the different expansion coefficients of the shaft and housing materials , causing the bearing clearance to decrease or increase.

According to experience, the most suitable working clearance for ball bearings is close to zero, and a small amount of working clearance should be maintained for roller bearings. In components requiring good support rigidity, the bearing is allowed to have a certain amount of preload. Under normal working conditions, the basic group should be preferred, so that the bearing can get the proper working clearance. When the basic group cannot meet the use requirements, the auxiliary group clearance should be selected. The large clearance assist group is suitable for the interference fit between the bearing and the shaft and housing bore. The small clearance auxiliary group is suitable for occasions requiring high rotation accuracy, strict control of the axial displacement of the housing hole, and reduction of vibration and noise. In addition, when the rigidity of the bearing needs to be improved or the noise needs to be reduced, the working clearance should take a further negative value, and when the bearing temperature rises sharply, the working clearance should take a further positive value, etc., and a specific analysis must be made according to the operating conditions. .

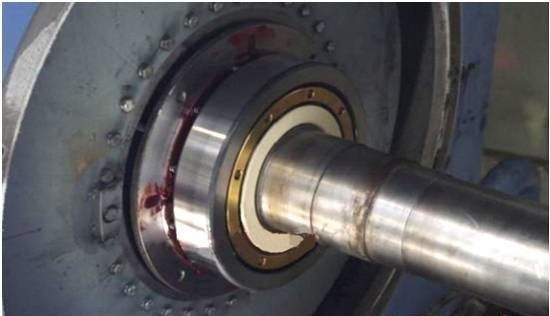

Since the working clearance is closely related to the life, temperature rise, vibration and noise of the bearing, the control of the internal clearance of the bearing is very important. Motor bearings must have proper internal clearance to maintain good operation. The original clearance of the bearing is a very important indicator. Therefore, before the bearing is assembled, a feeler gauge should be used to check the original clearance, and at the same time, the contact resistance between the inner ring and the armature shaft should be measured to ensure its reliable contact. After the motor is assembled, the bearing clearance is the matching clearance. If the clearance is too small at this time, it will cause the bearing to overheat, cause the inner ring to expand, make the clearance smaller and smaller, and eventually cause the bearing to burn out; If it is too large, the rollers will be unevenly stressed, resulting in additional vibration, which is easy to damage the bearing. Therefore, after the total assembly of the motor, the feeler gauge should be used to measure the clearance of the bearing after assembly. If the clearance is found to be unqualified, it must be disassembled and repaired. The original radial clearance of ZWZ bearings is all in line with GB4604. Radial clearance values apply to unmounted and unloaded bearings. Bearings larger or smaller than the standard value of clearance can also be produced according to user requirements.

Post time: Mar-23-2022