Nowadays, the development speed of the power industry is getting faster and faster, and the application of insulated bearings is becoming more and more common. Due to its special properties, insulated bearings are suitable for motors and generators, especially in frequency conversion motors. Our company has mainly engaged in insulated bearings for many years and has a rich understanding of insulated bearings. There are many things that need to be paid attention to when using insulated bearings in motors, especially when repairing motors. The following insulated bearing company will introduce you to the precautions of insulated bearings when repairing motors.

There are generally two methods for bearing insulation, one is to choose insulated bearings, and the other is to choose insulated bearing chambers.

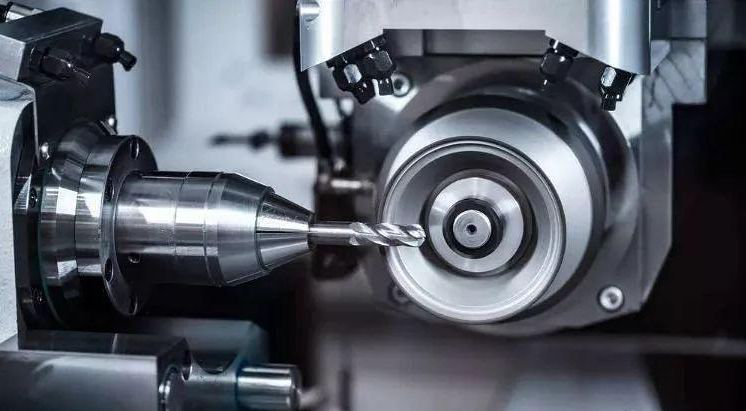

Insulated bearings: Insulated bearings can be divided into inner ring coating, outer ring coating and rolling elements made of ceramic materials. The inner ring coating and outer ring coating are plasma sprayed to coat the ceramic material on the bearing surface. This coating can still maintain its unique insulation performance in a humid environment; while the ceramic material rolling body type insulated bearing, The rolling element is made of ceramic material, and the ceramic material rolling element insulated bearing has excellent current resistance capability, so it can be effectively insulated.

Insulated bearing room: Generally, a PTFE film is used in the inner hole of the end cover bearing to be pasted on the inner hole of the bearing to insulate the bearing and the end cover and cut off the path of bearing current.

No matter which type of insulation has its own advantages, the following points should be paid attention to when repairing the insulated bearing of the motor.

1. Selection and control of tolerances of the shaft and bearing chamber of the insulated bearing: the bearing should be pressed into the bearing to maintain flexible rotation without a sense of blocking. If there is obvious inflexible rotation, it means that the size of the bearing is too large, and the bearing tolerance needs to be lowered. If the bearing is pressed into the shaft and turned by hand, there is an obvious sense of “sand”, it may be that the roundness of the shaft is not good or the tolerance of the shaft is too large.

2. The method of assembly of insulated bearings: Because insulated bearings are high-precision products, improper assembly can easily damage the raceway of the bearing and cause damage to the bearing. Insulated Bearing Company reminds operators to use special molds when assembling the bearings, and not to knock them at will. When pressing in the shaft, only the small ring can be forced, and when the large ring is pressed, only the large ring can be forced. Air pressure or hydraulic pressure must be used when the bearing is assembled. The upper and lower molds must be in a horizontal state during press-fitting. If there is an inclination, the bearing channel will be damaged by force, which will cause abnormal noise in the bearing.

3. Prevention of assembling foreign matter: When the bearing is installed on the rotor for dynamic balancing, it is easy to enter the iron filings generated during dynamic balancing into the bearing, so it is best to perform dynamic balancing before installing the bearing. Do not apply oil or grease to the bearing chamber. If it must be coated, it must be controlled well, and it must not accumulate in the bearing chamber.

4. Prevention of paint rust: The characteristics of paint rust mostly occur in enclosed motors. The sound of the motor is normal during assembly, but after a period of time in the warehouse, the abnormal noise of the motor will increase, and the removal of the bearing will cause serious production. Rust phenomenon. Many people will think it is a bearing problem, but it is mainly a problem of insulating paint. The main reason is that the acidic substances volatilized from the insulating paint are transformed into corrosive substances under a certain temperature and humidity, which corrodes the bearing channel and then causes the bearing to be damaged. The best solution now is to choose a good insulating paint, and ventilate for a period of time after drying before assembling.

The above is the precautions for insulated bearings introduced by the insulated bearing company during motor maintenance. I hope to help you work better and bring some help to your business. In addition, if you need insulated bearings, please call to order our products.

Post time: Oct-09-2021