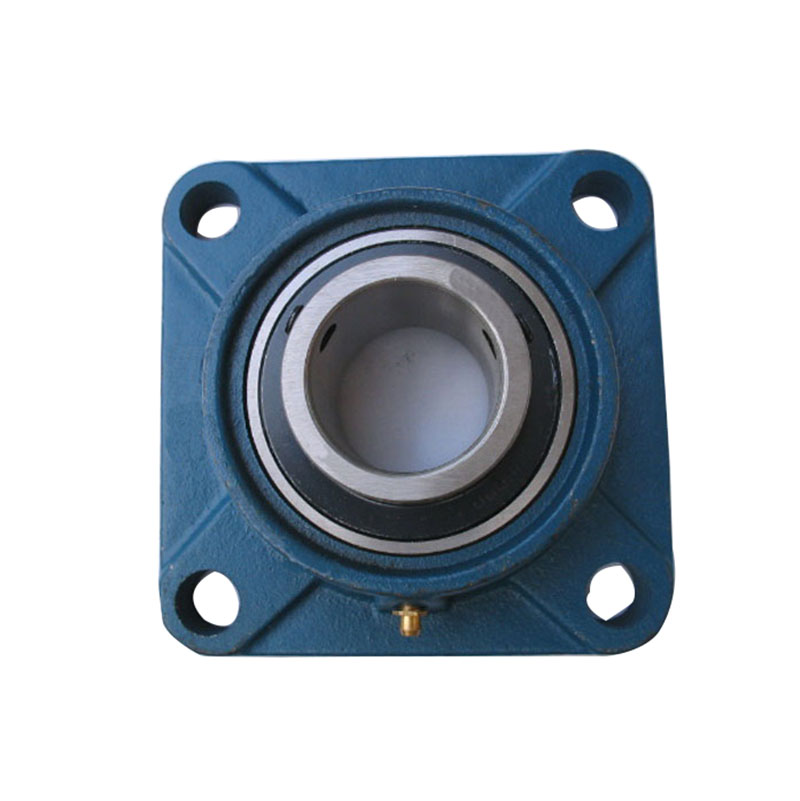

Radial ball bearings are critical components in various mechanical systems, ensuring smooth rotational motion and reducing friction between moving parts. Proper maintenance of these bearings is essential for extending their lifespan and ensuring the efficiency of the machinery they support. As an industry leader, Xinri Bearing has built its reputation on producing high-quality bearings and offering expert guidance to optimize their performance. This article outlines key maintenance procedures for radial ball bearings while exploring industry trends and insights.

Why is Radial Ball Bearing Maintenance Important?

Radial ball bearings are used in numerous applications, including automotive systems, industrial machinery, and consumer products. Over time, factors such as contamination, inadequate lubrication, or improper handling can degrade bearing performance, leading to increased friction, noise, and potential system failure. Regular maintenance not only helps prevent these issues but also reduces downtime and enhances cost performance in industrial operations.

Key Maintenance Procedures for Radial Ball Bearings

- Regular Inspection

Inspect bearings periodically to identify early signs of wear or damage. Look for common issues such as pitting, discoloration, or unusual noise during operation. Early detection helps prevent more extensive damage to machinery.

- Proper Lubrication

Lubrication is vital for reducing friction and preventing overheating. Use high-quality lubricants recommended by the manufacturer, and avoid over-lubrication, which can attract contaminants. Xinri Bearing provides detailed specifications for lubrication, ensuring compatibility with various operating conditions.

- Cleaning

Remove and clean the bearings using non-corrosive solvents. Dry them thoroughly to prevent moisture-induced corrosion. Always handle bearings with clean tools to avoid contamination.

- Avoid Overloading

Bearings are designed to handle specific loads. Overloading them can lead to premature failure. Ensure your machinery operates within the bearing’s specified load limits as defined by the manufacturer.

- Monitor Alignment

Misaligned bearings can cause uneven load distribution, increasing wear. Regularly check alignment to maintain smooth operation and prolong the bearing’s service life.

Xinri Bearing: A Trusted Partner in Bearing Solutions

With decades of expertise, Xinri Bearing has become a trusted supplier and manufacturer of high-performance bearings for various industries. By integrating advanced R&D and precision manufacturing technologies, Xinri Bearing ensures that its products meet the highest standards of reliability and durability.

Their innovative approach extends beyond manufacturing, offering comprehensive maintenance guides and technical support to clients, including OEM/ODM solutions for customized needs.

Industry Trends and Insights

- Focus on Sustainability

The global bearing industry is increasingly shifting toward environmentally friendly solutions. Xinri Bearing is at the forefront of this trend, using sustainable materials and energy-efficient processes in their production facilities. - Digital Monitoring Systems

IoT-enabled condition monitoring systems are transforming how bearings are maintained. These systems provide real-time data on parameters such as temperature, vibration, and lubrication levels, allowing predictive maintenance to minimize unplanned downtime. - High-Precision Bearings

Demand for high-precision bearings is rising in industries like aerospace and robotics. Xinri Bearing’s cutting-edge designs cater to these sectors, ensuring superior performance in demanding applications.

Why Choose Xinri Bearing?

Xinri Bearing not only provides premium radial ball bearings but also offers a full spectrum of services, including maintenance support, distribution, and tailored solutions for OEM/ODM projects. With a well-established presence in China and a global distribution network, Xinri Bearing ensures reliable supply and unparalleled technical expertise.

Whether you are a manufacturer, distributor, or industrial operator, Xinri Bearing is your partner for high-quality bearings and innovative solutions. By following proper maintenance procedures and leveraging industry advancements, you can maximize the performance and longevity of your radial ball bearings, keeping your machinery running smoothly and efficiently.

Conclusion

Regular maintenance is critical for optimizing the performance and extending the lifespan of radial ball bearings. Companies like Xinri Bearing provide not only superior products but also the guidance needed to ensure operational success. As industry trends continue to evolve, Xinri Bearing remains committed to delivering innovative, sustainable, and high-performance bearing solutions for a wide range of applications.

Post time: Nov-21-2024