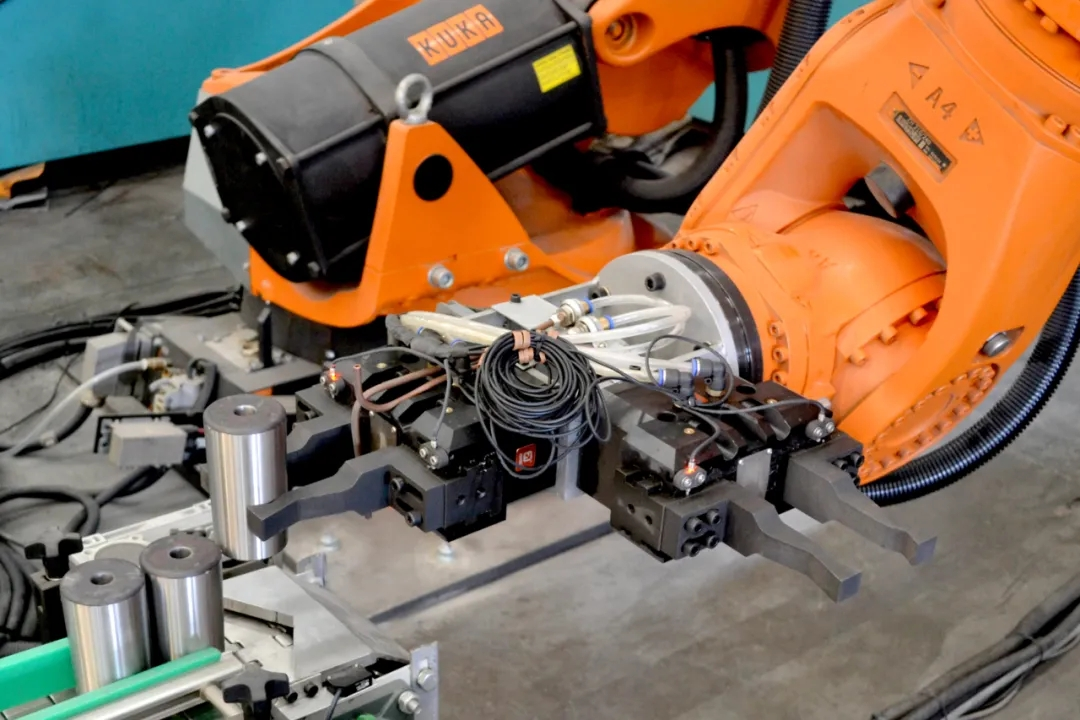

Since the beginning of this year, Luoyang Huigong Bearing Technology Co., Ltd. has stepped up its efforts to upgrade the automation of its production lines. At present, several robots are officially “on-the-job” operations, realizing automated operations that replace employees with robots.

The traditional mode before the robot is on duty is that one employee operates one or two machine tools. Now that the robot “on duty” replaces the employee’s work, the employee only needs to send program instructions to the robot, and the robot will accurately position the workpiece according to the program instructions, automatically Carrying out fixed-point grabbing of the rollers, completing the connection actions such as loading and unloading, realizes efficient and orderly connection during the entire processing process, without manual operation.

With the company’s next investment in automation equipment and technological upgrading, XRL bearing production site will achieve many robot “on-duty” operations, which will further enhance the company’s production capacity and processing efficiency.

Post time: Dec-22-2021